The BMW E36 is a popular choice for manual transmission swaps, offering enhanced driving experience, control, and connection to the road, appealing to enthusiasts seeking improved performance.

1.1. Overview of the BMW E36 Model

The BMW E36, produced from 1990 to 2000, is a compact executive car known for its balanced performance, handling, and luxury. Available in sedan, coupe, convertible, and wagon body styles, it catered to a wide audience. The E36 featured a range of engines, from inline-4 cylinders to V8 powerplants in the M3 model, offering versatility for both daily driving and enthusiasts. Its robust design, reliability, and timeless styling have made it a favorite among BMW enthusiasts. The E36’s blend of affordability, performance, and aftermarket support has solidified its status as a popular choice for modifications, including manual transmission swaps.

1.2. Popularity of Manual Transmissions in the E36

1.3. Benefits of a Manual Swap for E36 Owners

Performing a manual swap on a BMW E36 offers numerous benefits, including enhanced driver engagement and control. Manual transmissions provide quicker acceleration and better fuel efficiency compared to automatics. Additionally, manual swaps often increase the car’s resale value, as many enthusiasts prefer the driving experience of a manual gearbox. The ability to customize the transmission with aftermarket components further enhances performance. Moreover, the sense of accomplishment from completing the swap is rewarding for DIY enthusiasts. Overall, a manual swap transforms the E36 into a more responsive and enjoyable vehicle, aligning with its reputation as a driver’s car.

Planning and Preparation for the E36 Manual Swap

Planning involves budgeting, choosing the right transmission, and gathering essential tools. Research compatibility, prepare the workspace, and allocate sufficient time for the swap to ensure success.

2.1. Budgeting for the Manual Swap

Budgeting is crucial for a successful manual swap. Costs include the transmission, clutch, flywheel, and labor. Estimate between $2,500 to $4,500 depending on parts quality and complexity. Ensure funds cover unexpected expenses and tools. Plan wisely to avoid overspending by researching deals and considering used or refurbished components. Allocate funds for professional help if needed. Proper budgeting ensures the swap proceeds smoothly without financial strain, making the upgrade enjoyable and stress-free.

2.2. Choosing the Right Manual Transmission for Your E36

Choosing the right manual transmission for your E36 is essential for optimal performance and reliability. The most common options are the Getrag 260 and Getrag 265, both compatible with the E36’s engine lineup. Consider the engine type and intended use—260 for smaller engines, 265 for larger ones. Ensure compatibility with your E36’s model year and drivetrain. Used transmissions are cost-effective but inspect for wear. Rebuilt units offer better reliability. Research suppliers and seek advice from forums or specialists to make an informed decision. The correct transmission ensures smooth operation and enhances driving enjoyment.

2.3. Essential Tools and Equipment Needed

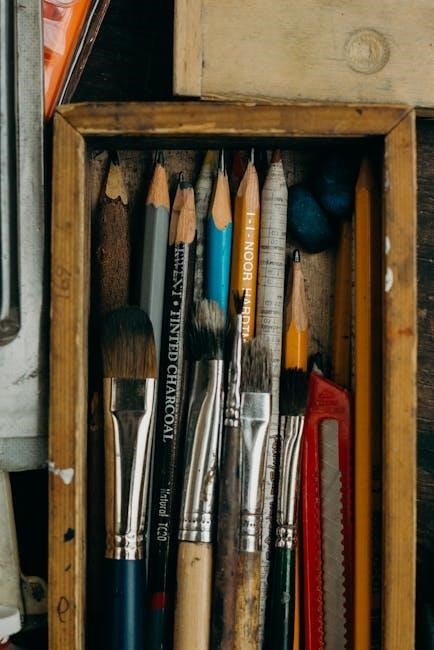

Performing an E36 manual swap requires a variety of tools and equipment to ensure the job is done safely and efficiently. Basic tools include wrenches, sockets, and screwdrivers, while specialized tools like a transmission jack, universal joint puller, and clutch alignment tool are essential. A good jack and jack stands are necessary for lifting and securing the car. Brake bleeding equipment and fluid pumps will also be needed for post-installation adjustments. Protective gear such as gloves and safety glasses should always be worn. Having a well-organized workspace and access to a hydraulic press for bushing removal can save time. Ensure all tools are in good condition to avoid complications during the swap.

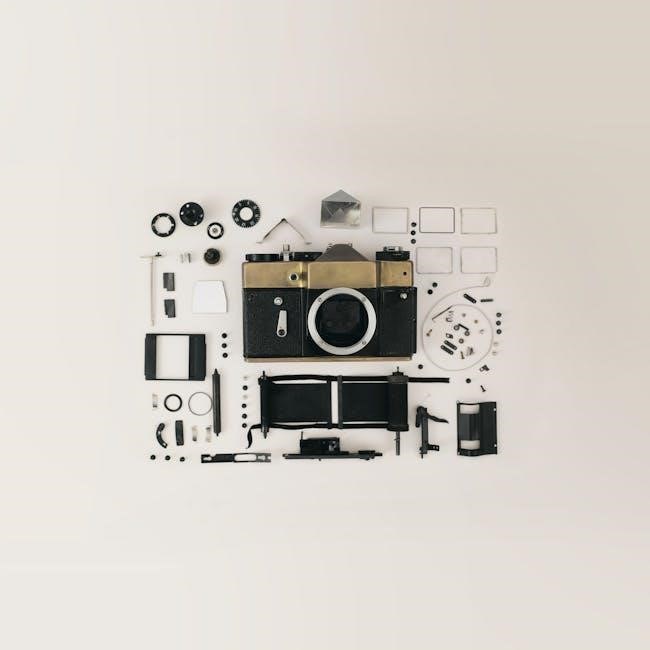

Tools and Parts Required for the Swap

A successful E36 manual swap demands the right tools and parts, ensuring compatibility and reliability. Specialized tools, genuine BMW components, and high-quality aftermarket alternatives are essential for a seamless process.

3.1. List of Specialized Tools for the Job

Performing an E36 manual swap requires a set of specialized tools to ensure precision and safety. A transmission jack is essential for handling the gearbox, while a socket set and wrenches are needed for bolting and unbolting components. A torque wrench is crucial for proper torque specifications during reassembly. Additional tools include a clutch alignment tool, flywheel puller, and dial indicator for measuring surfaces. A universal joint and adapter for the driveshaft are also necessary. These tools are critical for a successful swap, preventing damage to components and ensuring proper installation.

3.2. Parts Compatibility and Where to Source Them

Ensuring parts compatibility is critical for a successful E36 manual swap. Key components include a manual transmission, clutch kit, flywheel, and drivetrain mounts. These parts must align with your E36’s engine and chassis specifications. Compatible transmissions include the BMW 328i or M3 units, while the clutch and flywheel should match the transmission’s spline count. Sourcing parts from reputable dealers, specialty shops, or online forums is recommended. Genuine BMW parts are ideal, but high-quality aftermarket alternatives can also work. Always verify compatibility with your vehicle’s specific model year and configuration to avoid installation issues.

3.3. Importance of Genuine BMW Parts

Using genuine BMW parts for your E36 manual swap ensures optimal performance, reliability, and longevity. These parts are specifically designed for your vehicle, guaranteeing a perfect fit and compatibility. Genuine components are built to BMW’s strict quality standards, reducing the risk of premature wear or failure. They also maintain your car’s factory warranty and resale value. While aftermarket alternatives may be cheaper, genuine parts are more durable and less likely to cause issues down the line. Prioritizing genuine BMW parts ensures a seamless and trouble-free manual swap, preserving your E36’s integrity and performance.

Step-by-Step Guide to the E36 Manual Swap

This section provides a detailed, sequential approach to replacing your E36’s automatic transmission with a manual one, ensuring a smooth and successful swap process.

4.1. Removing the Automatic Transmission

Removing the automatic transmission is a critical first step in the E36 manual swap. Begin by raising the car on a lift or jack stands for safe access. Disconnect the battery to prevent electrical issues. Drain the transmission fluid and remove the driveshaft. Next, disconnect the transmission cooler lines, electrical connectors, and hydraulic lines. Remove the heat shields and transmission crossmember bolts. Carefully lower the transmission using a transmission jack, ensuring it is securely supported. Finally, separate the transmission from the engine by removing the remaining bellhousing bolts. Properly label and store all removed components for later use or disposal. This step requires patience and precision to avoid damage to surrounding components.

4.2. Preparing the Car for Manual Transmission Installation

After removing the automatic transmission, the next step is to prepare the car for the manual transmission. Start by cleaning the bellhousing and surrounding areas to ensure a smooth installation. Inspect the clutch pedal assembly and hydraulic system for any damage or wear. Install the new clutch and pilot bearing onto the flywheel, ensuring proper alignment. Check the transmission tunnel for any obstructions or modifications needed to accommodate the manual gearbox. Apply a thin layer of grease to the input shaft and pilot bearing for smooth engagement. Finally, ensure all electrical and hydraulic connections are ready for the manual setup. Proper preparation ensures a seamless installation process.

4.3. Installing the Manual Transmission

Installing the manual transmission requires precision and care. Start by aligning the transmission with the bellhousing, ensuring the input shaft engages with the clutch. Use a transmission jack or lift to maneuver the unit into place. Secure the transmission with the provided mounts, tightening all bolts evenly. Reconnect the driveshaft, making sure it is properly seated; Attach the gearshift assembly and linkages, ensuring they are aligned correctly. Connect the electrical connectors for the reverse light and speed sensor. Finally, double-check all connections and mounts for tightness. Having a helper can simplify the process. Proper alignment and secure mounting are crucial for smooth operation.

4.4. Connecting the Gearbox to the Engine

Connecting the gearbox to the engine is a critical step in the manual swap. Start by aligning the transmission’s input shaft with the clutch disc on the engine. Use a clutch alignment tool to ensure proper engagement. Once aligned, secure the transmission to the engine using the appropriate mounts and bolts. Tighten all connections evenly to avoid misalignment. Reattach the driveshaft, ensuring it is properly seated and supported by the center bearing. Connect the gearshift linkage, adjusting it for smooth operation. Finally, hook up any electrical connectors for sensors like the speed sensor or reverse light switch. Double-check all connections for tightness and proper alignment to ensure reliable power transfer.

4.5. Reinstalling the Driveshaft and Other Components

Reinstalling the driveshaft and other components is essential for restoring power delivery. Begin by carefully sliding the driveshaft into the differential, ensuring it is fully seated. Secure the center bearing by tightening its mounting bolts in a star pattern. Reattach any heat shields or protective covers removed during the swap. Reconnect the reverse light switch and any other electrical components. Inspect the driveshaft for any signs of damage or wear. Once everything is in place, tighten all bolts to the specified torque. Finally, double-check the driveshaft alignment to ensure proper operation and avoid vibration. Proper installation ensures smooth power transfer and prevents future issues.

4.6. Bleeding the Clutch System

Bleeding the clutch system is crucial to eliminate air bubbles and ensure proper pedal feel. Start by using a clutch bleeding kit specific to your E36. Attach the bleeder hose to the slave cylinder and submerge the other end in fresh brake fluid. Pump the clutch pedal several times to pressurize the system, then crack open the bleeder valve to release air and fluid. Repeat this process until the fluid flows cleanly without bubbles. Use a power bleeder for efficiency, if available. Finally, test the pedal to ensure a firm, responsive feel. Proper bleeding ensures consistent clutch engagement and avoids spongy or unresponsive behavior during driving.

4.7. Finalizing the Installation

After installing the manual transmission, reconnect all components, such as the gearshift linkage, reverse light switch, and electrical connectors. Ensure the transmission mounts are securely bolted to the chassis. Double-check the driveshaft installation and tighten all bolts to specified torque values. Test the gearshift operation to confirm smooth engagement in all gears. Reconnect the battery and test the clutch pedal for proper function. Inspect all fluid connections for leaks and top off the transmission fluid as needed. Refer to your service manual for final torque specifications and adjustments. A thorough inspection ensures reliability and prevents issues down the road. Proper finalization guarantees a seamless driving experience.

Post-Installation Steps and Adjustments

After installation, test the transmission, clutch, and electrical connections. Ensure proper fluid levels and adjust components as needed for smooth operation and reliability.

5.1. Testing the Manual Transmission

After installation, thoroughly test the manual transmission to ensure proper functionality. Start by idling the car and shifting through all gears to check for smooth engagement. Monitor the transmission temperature and listen for unusual noises. Perform a slow test drive in a safe area, paying attention to clutch pedal feel and gear transitions. Test acceleration from a standstill and shifting at varying speeds. Verify that the transmission does not slip or hesitate between gears. Address any issues immediately, such as grinding or difficulty engaging gears, to prevent further damage. This step ensures the swap was successful and the car is ready for normal operation.

5.2. Adjusting the Clutch Pedal and Slave Cylinder

Adjusting the clutch pedal and slave cylinder ensures smooth gear transitions and proper engagement. Begin by locating the clutch pedal assembly under the dashboard. Check the connecting rod between the pedal and master cylinder, adjusting it to achieve the desired pedal feel. Tighten or loosen the rod using the appropriate nut or bolt. Next, bleed the clutch system to remove air bubbles, ensuring hydraulic efficiency. Use brake fluid and a bleeding kit, carefully opening the slave cylinder’s bleeder valve and pumping the pedal to flush out air. After bleeding, test the pedal feel; it should be firm but not overly stiff. If the pedal is too soft, the clutch may not engage fully, while excessive stiffness can be uncomfortable. Fine-tune the master cylinder’s adjustment screw to set the pedal resistance, avoiding over-tightening to prevent seal damage. Finally, take the car for a test drive to assess smooth gear engagement and overall pedal performance. Refer to the service manual for specific torque specifications and adjustment guidelines to ensure everything is correctly set. Proper adjustment is crucial for optimal driving experience and longevity of the clutch system.

5.3. Checking for Leaks and Proper Functionality

After completing the manual swap, inspect the system for leaks and ensure all components function correctly. Start by examining the slave cylinder, master cylinder, and transmission housing for any signs of fluid leakage. Use a flashlight to illuminate hard-to-reach areas, such as the bellhousing and driveshaft connections. Check the clutch hydraulic lines for proper sealing and tighten any loose fittings. Test the drivetrain by starting the engine, engaging first gear, and listening for unusual noises. Press the clutch pedal to ensure it disengages smoothly, and verify that the transmission shifts gears without resistance. Take the car for a short drive to confirm smooth acceleration and shifting. Finally, inspect the transmission fluid level and top it off if necessary. Catching issues early prevents costly repairs and ensures a reliable driving experience.

5.4. Updating the ECU for Manual Transmission

Updating the ECU is crucial after a manual swap to ensure proper communication between the engine and transmission. The stock ECU is calibrated for an automatic transmission, so manual swap requires reprogramming. Use a BMW-specific tuner or consult a specialist to refl ash the ECU with manual transmission software. This ensures correct throttle response, clutch engagement, and gear shift timing. Failure to update the ECU can result in poor drivability, rough idling, or even stalling. After updating, test the car to confirm smooth operation. This step guarantees optimal performance and compatibility, making the swap complete and reliable.

Common Issues and Troubleshooting

Common issues during an E36 manual swap include clutch master cylinder problems, gear engagement difficulties, and transmission noise. These can often be resolved with adjustments or replacements.

6.1. Common Problems During the Swap

During an E36 manual swap, common issues include improper clutch master cylinder alignment, leading to a spongy pedal or loss of clutch function. Gear engagement problems may arise from misaligned or damaged synchros. Transmission leaks from the pan or bellhousing gasket are frequent due to improper sealing. The driveshaft may not fit properly, causing vibration or noise. Additionally, incorrect transmission mounting can result in crossmember interference. Electrical issues, such as faulty sensors or wiring, can disrupt gear position signals to the ECU. These problems often stem from improper installation or incompatible parts, emphasizing the need for precision and correct components during the swap process.

6.2. Solving Clutch Master Cylinder Issues

Clutch master cylinder problems during an E36 manual swap often stem from improper installation or air in the system. Start by bleeding the clutch master cylinder thoroughly using a vacuum or manual bleeding kit. Ensure the clutch master cylinder is properly aligned with the clutch slave cylinder to maintain consistent pressure. If the pedal feels spongy or lacks engagement, check for fluid leaks or worn seals. In severe cases, replacing the master cylinder or rebuilding it with genuine BMW parts may be necessary. Properly securing the cylinder and ensuring the hydraulic system is functioning correctly will resolve most issues and restore smooth clutch operation.

6.3. Fixing Gear Engagement Problems

Gear engagement issues during an E36 manual swap can arise from misalignment or improper installation of the transmission. Ensure the transmission is correctly aligned with the engine, using alignment dowels to prevent shifting problems. Check the clutch cable or hydraulic system for proper adjustment, as a misadjusted clutch can prevent gears from engaging smoothly. Inspect the pilot bearing and gear synchronizers for wear or damage, replacing them if necessary. Verify that the gearshift linkage is securely attached and adjusted properly. If issues persist, consult a BMW repair manual or seek guidance from experienced technicians to ensure all components are functioning correctly and aligned precisely.

6.4. Addressing Transmission Noise

Transmission noise after an E36 manual swap can be caused by worn bearings, loose mounts, or improper installation. Inspect the transmission mounts and replace them if they show signs of wear. Check the input and output shaft bearings for damage or excessive play. Ensure all bolts and fasteners are tightened to the correct torque specifications. If noises persist, inspect the drivetrain for alignment issues or worn components like the differential or driveshaft. Consult a BMW repair manual for specific troubleshooting steps. Addressing these issues promptly can prevent further damage and ensure smooth operation of the manual transmission.

Maintenance and Upgrades After the Swap

Regular maintenance ensures optimal performance. Check transmission fluid levels, inspect for leaks, and replace worn components. Upgrades like lightweight flywheels or performance clutches can enhance driving dynamics.

7.1. Regular Maintenance for the Manual Transmission

Regular maintenance is crucial to ensure the longevity and performance of your E36’s manual transmission. Check the transmission fluid level regularly, as low levels can lead to premature wear. Inspect the gearbox for any signs of leaks, particularly around the seals and gaskets. Monitor the clutch pedal feel and adjust it if necessary to maintain proper engagement. Replace the clutch master and slave cylinders if they show signs of failure. Additionally, inspect the driveshaft and guibo for wear or damage. A transmission fluid change is recommended every 30,000 to 60,000 miles, depending on usage. Regularly cleaning the transmission pan and replacing the filter can also prevent contamination. Addressing issues early prevents costly repairs and ensures smooth shifting. Consistent upkeep guarantees reliable performance and driver satisfaction.

7.2. Upgrading the Clutch for Better Performance

Upgrading the clutch is a popular modification for E36 owners seeking improved performance. A high-performance clutch kit, such as a lightweight or performance-oriented unit, can enhance acceleration and responsiveness. Ceramic or Kevlar clutches are excellent options for durability and heat resistance, especially for spirited driving. When upgrading, ensure the clutch aligns with your transmission and engine specifications. Consider pairing the clutch with an upgraded flywheel for smoother engagement and reduced weight. Proper installation is critical, so ensure the clutch is aligned correctly and the system is bled thoroughly. For optimal results, consult a professional or follow detailed guides to avoid complications. Upgrading the clutch can significantly elevate your driving experience.

7.3. Enhancing Gearbox Performance

Enhancing gearbox performance can significantly improve the driving experience of your E36. Upgrading to a lightweight flywheel reduces rotational mass, allowing for quicker acceleration and smoother shifting. Installing a high-quality gearbox oil with synthetic formulations ensures better lubrication and cooler operating temperatures. Additionally, a short shift kit can reduce the throw between gears, making shifts faster and more precise. For track or performance driving, consider upgrading to a close-ratio gearbox, which minimizes RPM drop between shifts. These modifications not only enhance performance but also provide a more engaging and responsive driving experience. Always ensure compatibility and consult a professional for complex upgrades.

7.4. Importance of Transmission Fluid Changes

Regular transmission fluid changes are crucial for maintaining the health and performance of your E36’s manual gearbox. Over time, the fluid becomes contaminated with metal shavings and debris, which can damage internal components. Fresh fluid ensures proper lubrication, reducing wear on gears and bearings. It also prevents corrosion and maintains optimal hydraulic pressure for smooth gear engagement. BMW recommends changing the transmission fluid every 30,000 to 60,000 miles, depending on driving conditions. Use a high-quality synthetic fluid specifically designed for manual transmissions to maximize performance and longevity. Neglecting this maintenance can lead to premature gearbox failure, making regular fluid changes a cost-effective preventive measure.

Community and Resources

The E36 community offers extensive support through forums, social media groups, and specialized workshops. Enthusiasts share knowledge, tips, and resources, making the manual swap process smoother and more accessible for DIYers and professionals alike.

8.1. Online Forums and Communities for E36 Enthusiasts

Online forums and communities are invaluable for E36 enthusiasts undertaking a manual swap. Platforms like Bimmerforums, Reddit’s r/BMW, and r/E36 provide extensive discussions, DIY guides, and troubleshooting tips. Members often share personal experiences, helping others avoid common pitfalls. Facebook groups dedicated to BMW enthusiasts also offer real-time support and advice. These communities foster collaboration, allowing members to learn from experts and novices alike. Whether seeking technical advice or emotional support during the swap, these forums are a cornerstone of the E36 community, ensuring no one feels isolated in their project.

8.2. Recommended Resources and Guides

For a successful E36 manual swap, leveraging recommended resources and guides is crucial. The Bentley Repair Manual provides detailed, model-specific instructions, while websites like E36Tech and Bimmerforums offer comprehensive DIY guides. YouTube channels dedicated to BMW modifications often feature step-by-step videos of the swap process. Additionally, forums like Reddit’s r/BMW and r/E36 host threads with personal experiences and tips. These resources cover technical aspects, troubleshooting, and best practices, ensuring enthusiasts have access to reliable information. By utilizing these guides, owners can confidently navigate the swap, avoiding common mistakes and achieving a seamless transition to manual transmission.

8.3. Professional Help and Workshops

For those who lack experience or confidence in performing an E36 manual swap, seeking professional help is highly recommended. Specialized BMW workshops and certified mechanics often have the expertise and tools to ensure a flawless installation. Many independent shops and BMW dealerships offer manual swap services, providing peace of mind and a warranty on their work. Additionally, some enthusiast-run garages specialize in E36 modifications and can offer tailored solutions. If DIY isn’t an option, professional assistance guarantees reliability and proper functionality. Researching reputable shops with positive reviews is essential to ensure a successful and stress-free swap experience.

9.1. Final Thoughts on the E36 Manual Swap

Completing an E36 manual swap is a rewarding experience that enhances driving engagement and connection with the vehicle. It offers improved control, fuel efficiency, and a more immersive driving experience. While challenging, the process fosters mechanical knowledge and problem-solving skills. The sense of accomplishment upon completion is significant, making it a worthwhile project for enthusiasts. Proper planning, research, and patience are key to a successful swap. The E36 community provides invaluable support, making the journey even more enjoyable. For those passionate about performance and personalization, the manual swap is a transformative upgrade that elevates the BMW E36 driving experience to new heights.

9.2. Encouragement for DIY Enthusiasts

Embarking on an E36 manual swap is a testament to your dedication and passion for DIY projects. This journey not only saves money but also empowers you with hands-on knowledge and skills. It’s a chance to deeply connect with your vehicle and understand its mechanics. While challenging, the process is incredibly rewarding, fostering confidence and pride in your abilities. Start with smaller projects to build your toolkit and experience. Engage with online forums and communities for guidance and inspiration. Remember, every wrench turn brings you closer to a more engaging and personalized driving experience. Embrace the challenge and enjoy the journey of transforming your E36.

0 Comments